Shanghai Yizhan Intelligent Technology Co., Ltd.

Contact: Manager Zuo

Phone: 18570610882

Landline number: 0519-89180823

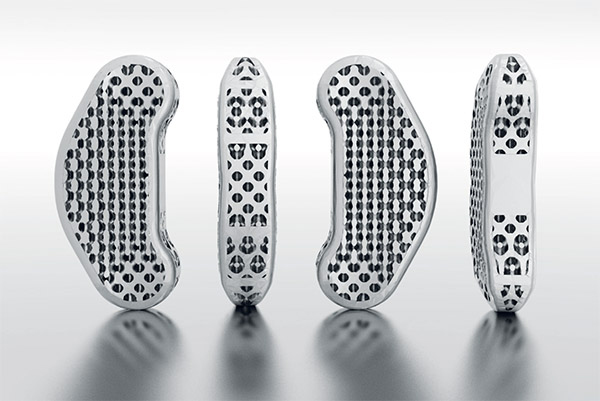

Email: 18682120284@163.com

Website: www.yizhan3d.cn

QQ: 156416789

Headquarters Address: Wisdom Bay 3D Museum, No. 6 Wenchuan Road, Baoshan District, Shanghai

Branch: Changzhou Yizhan 3D Technology Co., Ltd.

Branch address: No. 2-1, Haiye Building, Guihua Road, Zhonglou District, Changzhou, Jiangsu

■ Technical Principle

| ■ Printing process |

■ Technical advantages

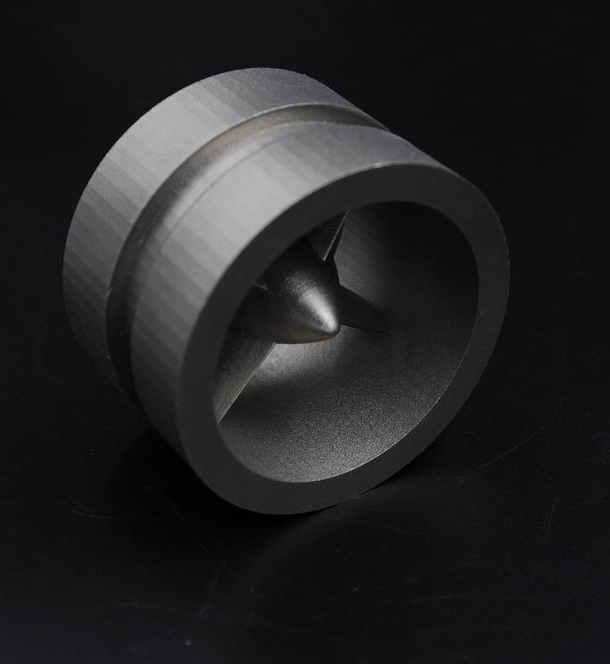

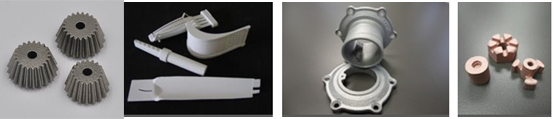

1.Adopting European advanced SLM forming system, any complicated structure can be formed at one time without welding. The delivery time is significantly reduced by 2/3.

2.A variety of metal materials are available. Common materials include titanium alloy, cobalt-chromium alloy, stainless steel, aluminum alloy, nickel-chromium alloy, copper, etc.

3.The overall cost reduction can reduce manufacturing costs by about 50%.

4.Help optimize product design, such as replacing the original solid body with a complex and reasonable structure, so that the weight of the finished product is lower, but the mechanical properties are better. Manufacturing metal structural parts that cannot be manufactured by traditional methods.

■ Applicable field

1. Mold manufacturing:

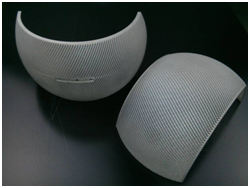

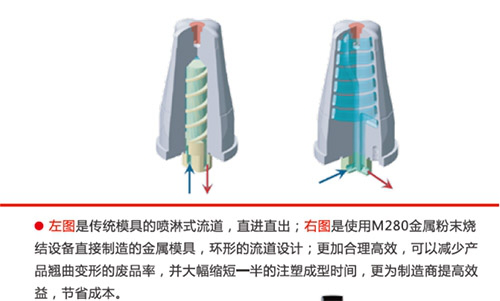

● Direct sintering of metal molds, including internal special-shaped runners and mold shells, such as injection molds, die-casting molds, and drawing molds.

● Mold repair and rapid manufacturing of other mold components.

● Break through the limitations of traditional mold processing capabilities and greatly improve the production efficiency and molding quality of final products (such as injection molded parts).

2. Aerospace:

According to statistics, 1,600 parts in the latest F-35 Lightening II aircraft are quickly manufactured using SLS technology. Airbus’s parent company, European Aerospace Defense Group (EADS), is already studying the use of 3D printing technology to manufacture aircraft, because it can not only reduce costs, but also make the weight of each component 65% lighter than traditional manufacturing methods.

● Dental: metal dentures, crowns and bridges, dental implant nails, removable dentures, orthodontic devices, etc.

● Orthopedics: artificial bone joints, bone implants, bone titanium plates, bone guides, etc.

● Medical equipment: surgical instruments, instruments, surgical positioning devices, metal prostheses, etc.

All rights reserved © 2020 Shanghai Yizhan Intelligent Technology Co., Ltd. 沪ICP备16045612号-2