Shanghai Yizhan Intelligent Technology Co., Ltd.

Contact: Manager Zuo

Phone: 18570610882

Landline number: 0519-89180823

Email: 18682120284@163.com

Website: www.yizhan3d.cn

QQ: 156416789

Headquarters Address: Wisdom Bay 3D Museum, No. 6 Wenchuan Road, Baoshan District, Shanghai

Branch: Changzhou Yizhan 3D Technology Co., Ltd.

Branch address: No. 2-1, Haiye Building, Guihua Road, Zhonglou District, Changzhou, Jiangsu

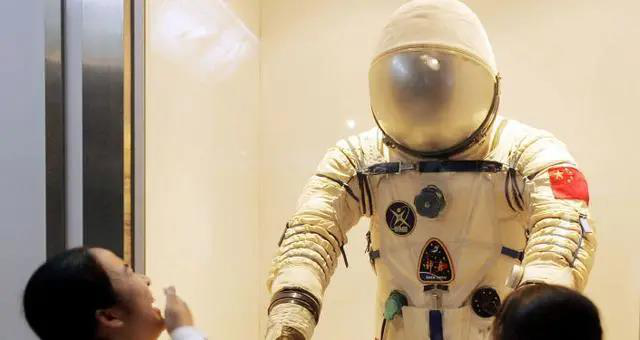

China's new carrier rocket "Long March 5B" successfully completed its first flight on May 5. During the period, the "composite space 3D printing system" carried by the manned spacecraft test ship successfully printed continuous fiber reinforced composite materials under microgravity conditions.

Professor Li Yong from the School of Materials Science and Technology of Nanjing University of Aeronautics and Astronautics introduced the development prospects of space 3D printing to the Russian Satellite News Agency.

Professor Li Yong said that 3D printing technology is of great significance to space exploration and will simplify the manufacturing of super large structures.

"Of the materials we need to launch into space, part of them cannot be taken into space due to the excessive size of the structure. With the development of composite space 3D printing technology, we can launch raw materials into space first, and then in space Carrying out on-orbit manufacturing of super large structures. It can be said that this technology is of great significance to our future exploration of space."

Experts also pointed out that continuous fiber reinforced composite materials are the main materials of modern spacecraft structures, with the characteristics of low density, high strength and light weight.

“节省重量对于物质进入太空是非常重要的关键因素,复合材料不仅重量轻,强度也比远高于金属,同时密度仅为1.6g/cm3,而大众所熟知的钢密度就有7.8g/cm3。”

3D printed composite materials are often used to make devices that cannot be launched into space: from special antennas to entire device components. The China National Space Administration has previously announced that China plans to become the world's first country to establish a base on the moon, which will be built using space 3D printing technology.

Space 3D printing is a very promising and rapidly developing field in the aerospace field, but the competition in this field has just begun.

The Made In Space company of the United States developed The Zero-Gravity printer for space 3D printing in 2016. If an astronaut needs supplies urgently, such as a special wrench, he can print it on the same day according to the drawings sent from the earth. Two of these printers have been successfully used on the International Space Station.

Researchers at the University of Birmingham have developed 3D metal printing technology for space. This device can overcome gravity and build spacecraft directly in orbit.

The National Aeronautics and Space Administration (NASA) funded 3D food printing technology and successfully developed the BeeHex printer, which can quickly print delicious pizza directly on orbit. But this technology is not currently being used, and it is planned to be used in long-distance space flights such as Mars travel in the future.

University of Southern California professor Berock Horchnives has developed a technology that can print houses on other planets. Robots can spread building materials—concrete layer by layer.

The main difficulty encountered by these ideas is how to find building materials in space. Therefore, NASA funded Made In Space company to manufacture special spacecraft that fly to asteroids to obtain resources and turn them into "manned warehouses." (Source: Science Frontier Antarctic Bear If there is any infringement, please contact and delete in time)

All rights reserved © 2020 Shanghai Yizhan Intelligent Technology Co., Ltd. 沪ICP备16045612号-2